INCREASING THE COMFORT, SPEED &

FINISH QUALITY BY HAND SANDING

Finixa Sharp Foam Pads are produced in an environmentally friendly production line, using only solvent-free adhesives! We believe that it is in everyone's interest to continue developing ecological production methods. We took our responsibility years ago by avoiding solvent-based adhesives as much as possible. Several sanding pads on the market today are still coated with a solvent-based adhesive.

Not only are these of lower quality, but they also contribute enormously to air pollution and greenhouse gas emissions. In addition, the solvent-free adhesive of Finixa Sharp Foam Pads is not only flexible, but more importantly, also much more elastic than solvent-containing adhesives.

This is a great advantage for the life span, as the Finixa Sharp Foam Pads are less likely to tear. The solvent-free adhesive is also heat-resistant. No performance reduction only because of the sanding friction.

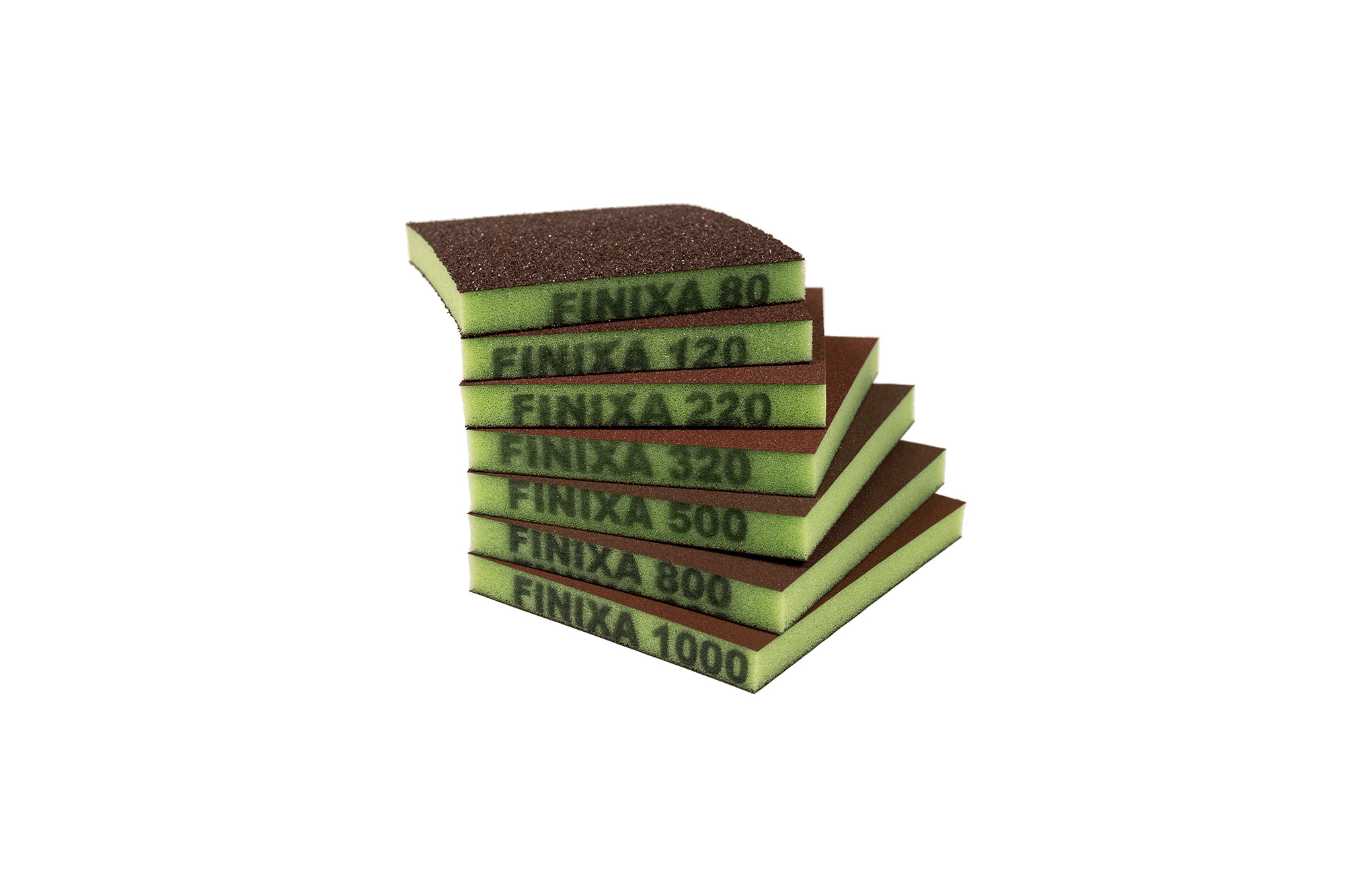

The Finixa Sharp Foam Pads are also coated with an extra ceramic-coated aluminum oxide grit, which makes them stronger and more durable. An additional advantage is that the ceramic coating also counteracts clogging, which also leads to a more uniform sanding result. The choice for the more expensive red ceramic AO grit makes the product unique and, in combination with the print on the side, clearly recognizable.